Automatic Sugarcane Bud Cutter Machine

Sugarcane is one of the most widely farmed crop over the globe. After harvesting sugarcane, cutting the sugarcane into chunks is a very time consuming process. All sugarcane cutting machines are either manual or semi automatic. This involves a lot of time and labor for each machine since the operation is not fully automatic.

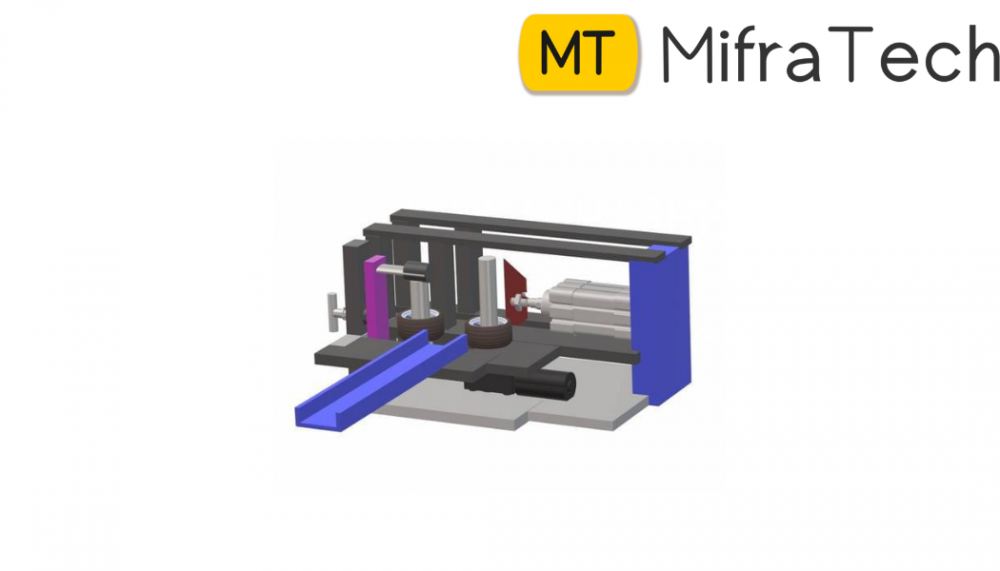

So here we propose a fully automatic sugarcane bud cutter that utilizes pneumatic power for automatic sugarcane cutting mechanism. The system makes use of a mini tabletop machine with a powerful motorized arrangement to push an entire sugarcane bud into the machine cutter. Once a sugarcane stick.bud is inserted a rubber gripper roller powered by geared motor is used to drive the stick towards the cutter at a specific rate.

A second roller is attached to the system through a screw based arrangement is used to push the sugarcane stick towards the other roller and maintain a grip over the cane. The system is further integrated with a pneumatic cylinder. A cutter blade is attached to the front end of the actuator. The pneumatic cylinder is powered by an external compressor to drive it back and forth using high air pressure.

This blade is used to cut the sugarcane bud into equal pieces in coordination with the feeder rollers. The machine uses rollers to pull in the sugarcane stick and cutter to cut it. Now the system also includes a controller circuitry that controls the cutting length of each piece. This allows the operator to cut the sugarcane in desired pieces.

Abstract

- In today’s world, the entire requirements are being fulfilled through automatic system. The demand for reducing the wastage of sugarcane. So the search of automatic system is completed by this project. One alternative to reduce the mass and improve the quality of seed for sugarcane would be to plant excised axillaries buds of cane stalk, popularly known as bud detector. This bud detector we can fit in bud chip to detect the bud. These bud detector are less bulky, easily portable and more economical material. The bud detector technology holds great promise in rapid multiplication of new sugarcane varieties. The problem of establishment and initial growth could be addressed by application of appropriate plant growth regulators and essential nutrients.

1. INTRODUCTION

Agriculture is one of the most significant sectors of the Indian Economy. Agriculture is the only means of living for almost two thirds of the workers in India. The agriculture sector of India has occupied 43% of India’s geographical area, and is contributing 16.1% of India’s GDP(Gross Domestic Product). There are number of crops grown by farmers. These include different food crops, commercial crops, oil seeds etc. sugarcane is one of the sugarcane is grown primarily in the tropical and sub-tropical zones of the southern hemisphere. Sugarcane is the raw material for the production of white sugar. It is also used for chewing and extraction of juice for beverage purpose. About 7.5% of therural population, covering about 45 million sugarcane farmers, their dependents and a large number of agricultural labors are involved in sugarcane cultivation, harvesting and ancillary activities.

2.RELATED WORK\LITERATURE REVIW

We visited to Agriculture field in Sangli and we understood the various problems of farmers such as stem cutting is a fault in which buds of sugarcane gets cut due to some human mistakes also the risk of injury is too high. This problem overcome by the project. Digital Image Processing deals with manipulation and analysis of images by using computer algorithm, so as to improve pictorial information for better understanding and analysis. Now a day’s sugarcane planting machines are used to reduce the human force and time. However, these machines do not have control on cutting location. This ultimately results into more population of sugarcane stalk which affect the yield. Sometimes, cut may appear on the bud as well, which results into no germinate on of the bud and we lose the seed. Also, it has no facility to identify diseased node, so planting of diseased nodes affects the yield and quality of the sugarcane . To overcome these problems image processing algorithm is developed and implemented for identification of node location on sugarcane stalk.

3.POPOSED METHODOLOGY

Change manual method in a automatic – by using appropriate capacity of single phase motor, gearbox which will reduce wastage and increase productivity as it will reduce strain on hands of worker and more on safety of operator. The research work in this domain was studied and new methods were developed to achieve desired goal.

4. SIGNIFICANCE AND SCOPE The system can fully Automatic and also utilize maximum of the technology and to do everything smartly and efficiently in order to reduce both energy and time consumption. It has vast scope in various industries because it saves time & Manpower

CONCLUSIONS In today’s world, Sugarcane automation has got importance in agricultural field. In most countries where agriculture is a main occupation automatic sugarcane bud cutting has played very significant role.The reason for choosing this project is to solve problem of farmer. To reduce man force & make their work easy by developing a new design also to reduce hard work.Our project is developing a device with user interface & with great looks &feel. The automation of sugarcane bud detection provides simplicity & convince to user. This project help to provide large amount of sugarcane bud in less period of time with little man power.In today’s world our project will stand in for sugarcane plantation in agricultural field.

IEEE PROJECTS | ECE best projects bangalore, CSE engineering projects , eee projects, data science best final year projects, projects ideas, engineering project center, web development projects, embedded final year best projects, mini projects

2128, Srinidhi complex, 3rd floor,16th B cross,

Bus stand road, near mother dairy cross, Yelahanka new town

BANGALORE, Karnataka 560064

We are providing best quality on projects with good services. We are giving free internship on project, Projects Based on IOT, Agriculture, Robotics, Pneumatics and Hydraulics, Aeronautical

Mifratech websites : https://www.mifratech.com/public/

Mifratech facebook : https://www.facebook.com/mifratech.lab

Mifratech instagram : https://www.instagram.com/mifratech/

Mifratech twitter account : https://twitter.com/mifratech

Contact for more information : [email protected] / 080-73744810 / 9972364704

mechanical engineering final year projects pdf

mechanical final year design project

mechanical engineering final year project ppt

m.tech mechanical final year projects

agriculture based mechanical engineering final year projects

final year projects for mechanical engineering related to automobile

mechanical engineering final year project analysis

mechanical final year project buy

best mechanical final year projects

final year mechanical projects done by iit students

buy final year projects for mechanical engineering

b.tech final year projects for mechanical engineering pdf

mechanical engineering final year project boiler

final year project for mechanical branch