ABSTRACT

Safety is the most vital part of any type of industry. In the mining industry safety and security is a fundamental aspect of all. To avoid any types of accidents mining industry follows some basic precautions. Still accidents take place in underground mines due to rise in temperature, increased water level, and methane gas leakage. Here we provide safety to worker. When worker in danger he can press panic switch inform security. To enhance safety in underground mines, a reliable communication system must be established between workers in underground mines and fixed ground mine system. The communication network must not be interrupted at any moment and at any condition. A cost effective zigbee based wireless mine supervising system with early-warning intelligence is proposed in this project. Worker status can be monitor over IOT.

INTRODUCTION

Mines are the world’s most dangerous place to work because in the mines, explosion often happens and thousand people are dying. And a recent report states that in such mine accidents an average of around 12,000 people have died. Coal is a nonsustainable origin that cannot be widely replaced by humans, there are several mishaps of coalmines occurring in the mines, and the diggers are putting their lives at risk, by working in the coal mines, even once in a while they end up losing their lives in the coal mines that are an unfortunate part. Mainly such mishaps happen as a direct result of the old equipment and wired devices, resulting in the end, mishandling, spillage of the noxious gases in the coal mines, pose tremendous hazards to the excavators inside the coal mines. So we’ve designed the coalmine protection system to stay away from this problem. We tackled the issues in our research by testing each of the information collected by the sensors, we use and finishing the analysis using the Thinger system. Controlling can be done automatically or manually.

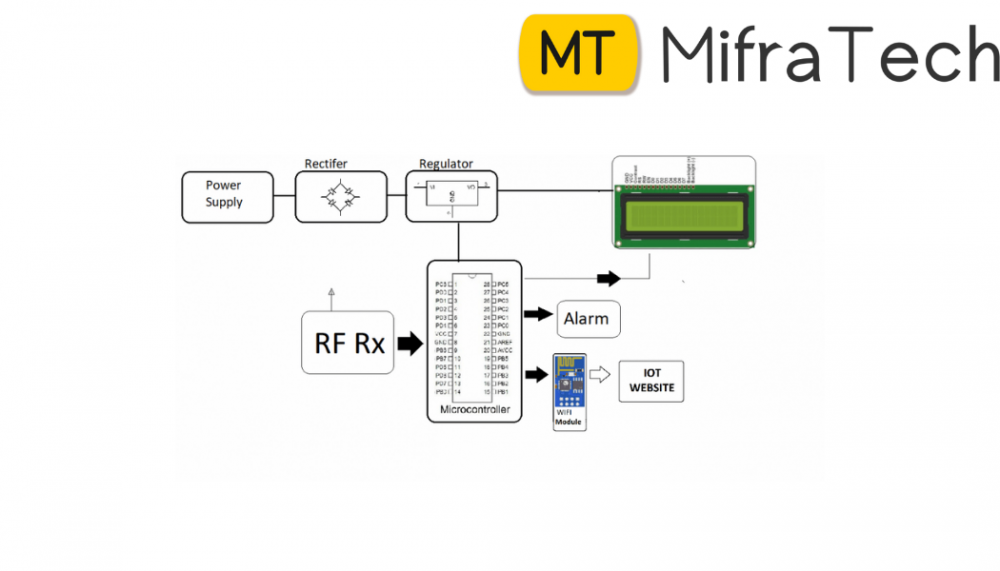

Block Diagram Description:

This monitoring system contains several components like boards (PIC board, Xbee module and Zigbee USB interfacing board), LCD (Liquid crystal display), different sensors and other small electronic components. This chapter gives a detailed review of each of this part along with its working principle. In this proposed system the coal mine safety systems are fixed with gas sensor modules, temperature sensor, water level sensor and relays. We integrate all the sensors to the controller. First we need to create an account in the ThingSpeak platform. In this system we mainly have monitoring and controlling systems. In monitoring system we monitor all the data from different sensors. Gas sensor detects the gas in the coal mine environment. If the gas level exceeds the normal level then the buzzer gets high so that the mine workers get notified. These sensor values are continuously uploaded to the cloud . for analysis and also for further use. The temperature and water level values are also monitored inside the coalmine and send data control unit through zigbee

1-ZIGBEE The CC2500 is a low-cost 2.4 GHz transceiver designed for very low-power wireless applications. The circuit is intended for the 2400-2483.5 MHz ISM (Industrial, Scientific and Medical) and SRD (Short Range Device) frequency band. The RF transceiver is integrated with a highly configurable baseband modem. The modem supports various modulation formats and has a configurable data rate upto 500 k Baud

2.LM35 TEMPERATURE SENSOR Outputs 10mV per Degree that can also be read directly on multimeter or read in to microcontroller. For example at 30 degree celcius it will output 300mV at linear scale. The LM35 series are precision integrated-circuit temperature sensors, whose output voltage is linearly proportional to the Celsius (Centigrade) temperature. The LM35 thus has an advantage over linear temperature sensors calibrated in ° Kelvin, as the user is not required to subtract a large constant voltage from its output to obtain 25 convenient Centigrade scaling.

3.-16*2 LCD DISPLAY LCD (Liquid Crystal Display)) screen is an electronic display module and find a wide range of applications. A 16x2 LCD display is very basic module and is very commonly used in various devices and circuits. These modules are preferred over seven segments and other multi segment LEDs. The reasons being: LCDs are economical; easily programmable; have no limitation of displaying special & even custom characters (unlike in seven segments), animations and so on. A 16x2 LCD means it can display 16 characters per line and there are 2 such lines. In this LCD each character is displayed in 5x7 pixel matrix. This LCD has two registers, namely, Command and Data.

4.GSM MODULE Fig-6 GSM Module This GSM modem has a SIM800A chip and RS232 interface while enables easy connection with the computer or laptop using the USB to Serial connector or to the microcontroller using the RS232 to TTL converter. Once you connect the SIM800 28 modem using the USB to RS232 connector, you need to find the correct COM port from the Device Manger of the USB to Serial Adapter. Then you can open Putty or any other terminal software and open an connection to that COM port at 9600 baud rate, which is the default baud rate of this modem.Once a serial connection is open through the computer or your microcontroller you can start sending the AT commands. When you send AT commands for example: "AT\r" you should receive back a reply from the SIM800 modem saying "OK" or other response depending on the command send.

5.- PIEZOELECTRIC BUZZER Features o sealed: yes o operating power: 3-6V DC / 25mA o extremely compact, ultrathin construction o no electrical noise o low current consumption yet high sound pressure level

6.-MQ- GAS SENSOR Using a MQ sensor it detect a gas is very easy. You can either use the digital pin or the analog pin to accomplish this. Simply power the module with 5V and you should notice the power LED on the module to glow and when no gas it detected the output LED will remain turned off meaning the digital output pin will be 0V. Remember that these sensors have to be kept on for pre-heating time (mentioned in features above) before you can actually work with it. Now, introduce the sensor to the gas you want to detect and you should see the output LED to go high along with the digital pin, if not use the potentiometer until the output gets high. Now every time your sensor gets introduced to this gas at this particular concentration the digital pin will go high (5V) else will remain low (0V). You can also use the analog pin to achieve the same thing. Read the analog values (0-5V) using a microcontroller, this value will be directly proportional to the concentration of the gas to which the sensor detects. You can experiment with this values and check how the sensor reacts to different concentration of gas and develop your program accordingly.

7.WATER LEVEL SENSOR Fig.13- Water Level Sensor A float switch is a device used to sense the level of liquid within a tank, it may actuate a pump, an indicator, an alarm, or other device. A float switch is a device used to sense the level of liquid within a tank. The switch may actuate a pump, an indicator, an alarm, or other device. Use them with hydroponics, saltwater tank, freshwater tank, gardening, aquariums for power head control, pet bowls, fish tanks, filtration, heating, pumps, ponds, basement alarms, boats, air condition drain pans, pressure washers, carpet cleaning mach, reef aquarium, fluid control, ice machines, coffee pots, marine, automotive, automobiles, tropical fish tanks, evaporator coils, condensation line, in relays, or what ever your project may be. It can be easily converted from normally open to normally close by inverting the float.

ADVANTAGES:

• Cost is less

•Provide wireless connection security.

• Improved services in coal mine.

AP PLICATIONS

• For Underground Mine System

Iot based engineering projects

iot based engineering projects

iot based projects for engineering students

iot based major projects

iot based major projects for ece

iot based projects for mechanical engineering

iot based final year engineering projects

iot based projects for final year engineering students

iot based final year projects for electronics engineering

iot based project

iot based best projects

iot based electrical engineering projects

Thank you for contacting Shield Technologies! Please let us know how we can help you.

For more information please do visit mifratech center.

Note : Find the best solution for electronics components and technical projects ideas

keep in touch with our social media links as mentioned below

Mifratech websites : https://www.mifratech.com/public/

Mifratech facebook : https://www.facebook.com/mifratech.lab

mifratech instagram : https://www.instagram.com/mifratech/

mifratech twitter account : https://twitter.com/mifratech