Pneumatic Sheet Bending Machine

ABSTRACT-

Normally the sheet metal cutting machine is manually hand operated for medium and small scale industries. This paper gives an insight about the automatic sheet metal cutting machine. Any automatic machine aimed for economical use of man. In this paper, pneumatic cylinder is used for cutting in easy way which can be use in small scale industries at lower cost. The sheet metal cutting machine works with the help of pneumatic double acting cylinder. The piston is connected to the moving cutting tool which is used to cut the sheet metal. The cutting process is operated by a direction control valve by using compressor. In manual method sheet metals goes to the scrap sometime because of wrong dimensions, improper cutting etc. Hydraulic machines are also used for sheet metal cutting. The main advantage of pneumatic sheet metal cutting machine is to improve product quality, repetition of work and increasing production rate.

INTRODUCTION

The production of iron and steel is of great importance for any country’s economy. This is because the iron and steel industry directly influences the development of a sustainable society and also it the basis for all other industries. Thus the trend in production and consumption in steel is also viewed as an indicator of the condition of the country’s economy. This is the reason why steel is called the “backbone” of a country’s economy. Hence by increasing the production of steel, we can help in the growth of our country’s economy, but this where the problem arises. A sheet metal cutting or a punching machine is very important to the sheet metal industry and since large scale industries are well established they can afford to equip themselves with hydraulically operated cutting and punching machines that generate a large amount of force and also are easily automated.

LITERATURE REVIEW

1) Automated Pneumatic Sheet Metal Cutting Machine Prajwal Poojary, Nishanth V, Nikhil, Niranjan Karkera, Ganesh Kalagi International Journal of Scientific & Engineering Research Volume 9, Issue 4, April-2018 243.

2) Design and Fabrication of Pneumatic Sheet Metal Cutting and Punching Machine International Journal of Engineering Research & Technology (IJERT) www.ijert.org Vol. 9 Issue 07, July-2020.

3) Fabrication Of A Pneumatic Sheet Metal Cutting Machine, Conference Paper · December 2017.

4) Pneumatic Sheet Cutting Machine- A Review International Journal of Scientific and Technical Advancements This is an industrial era and in order to have better surface finish and obtain a high degree of flexibility in the manufacturing processes in the industries, a lot of work is done on sheet metal.

One of the most common fabrication operations is metal bending. Bending of sheets and rods is done using bending machines mostly manually or using hydraulic pressure. Well we here develop a small and lightweight machine to bend low thickness metal sheets using pneumatic pressure.

This machine makes bending a single operator work whereas 2 operators are needed for all manual bending processes. The machine makes use of a pneumatic control valve to operate the machine. The user may use the valve using his/her thumb to control a joystick.

The valve button when pressed/moved drives pressure through the cylinder thus pressurizing and pushing the tool against the other v tool. This bends the sheet placed in between the tools to be bent as per the required angle.

The pneumatic cylinder is mounted on a sturdy supporting frame so that the force does not affect its stability. This ensures sturdy and accurate bends each time using just pneumatic pressure. The base frame and supporting frame give some clearance to the machine for easy sheet insertion and bending.

Components

· Pneumatic Actuator

· Pneumatic Pipes

· Pipe Joints

· Air Control Valve

· Base Frame

· Supporting Frame

· Mounts and Joints

· Screws and Bolts

Advantages

· High Speed Bending

· Portable Machine

· Single Operator Required

· Easy to Operate

Disadvantages

· Limited Thickness Bending

· Requires Air Compressor

Applications

· Sheet Metal Fabrication

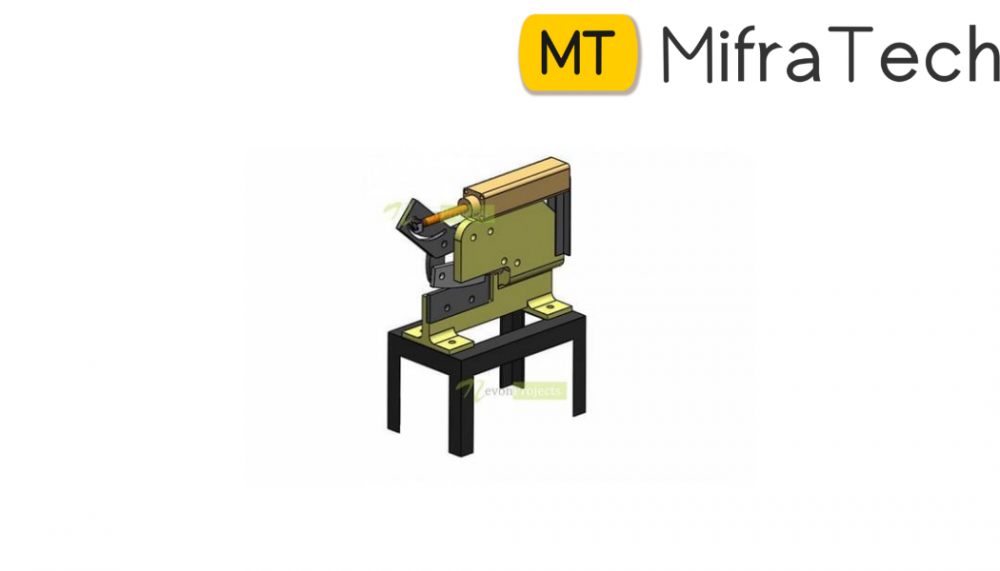

Block Diagrams

Front View

Top View

3d View

FUTURE SCOPE

1) It can be made hydraulic power operated by installing the gear oil pump at the place of air compressor and pneumatic cylinder arrangement.

2) It can be made rack and pinion operated or spring and lever operated.

3) The place where there is a scarcity of the electricity the electric motor operate compressor is replaced by an IC ENGINE installed compressor. Thus in future there are so many modifications, which we can make to survive the huge global world of competition.

ADVANTAGES

1. Hydraulics present certain advantages over pneumatics, but in a given application, pneumatic powered equipment is more suitable, particularly in industries where the factory units are plumbed for compressed air.

2. Moreover, to avoid corrosive actions, oil or lubricants are added so that friction effects can be reduced.

3. Compressed air is used in most of the machines and in some cases compressed carbon dioxide, whereas cutting process is become easy. 4. Fast cutting action is carried out. 5. Cutting without bending is achieved.

CONCLUSION

1. Thus our concept is complying to the demands of the customer whose use the products as well as those who are new.

2. The latent needs of customers, which they were not able to reciprocate properly is estimated successfully.

3. The individual functions were studied thoroughly and were evaluated by each group member.

4. Further study will involve more analysis about the product and comparison of similar products available in the market..

We are providing best quality on projects with good services. We are giving free internship on project, Projects Based on IOT, Agriculture, Robotics, Pneumatics and Hydraulics, Aeronautical

Mifratech websites : https://www.mifratech.com/public/

Mifratech facebook : https://www.facebook.com/mifratech.lab

Mifratech instagram : https://www.instagram.com/mifratech/

Mifratech twitter account : https://twitter.com/mifratech

Contact for more information : [email protected] / 080-73744810 / 9972364704

IEEE PROJECTS | ECE best projects bangalore, CSE engineering projects ,

2128, Srinidhi complex, 3rd floor,16th B cross,

Bus stand road, near mother dairy cross, Yelahanka new town

BANGALORE, Karnataka 560064

mechanical final year projects

mechanical engineering final year projects on automobile

mechanical engineering final year projects on thermal

mechanical engineering final year projects on agriculture

buy mechanical final year projects

mechanical engineering final year projects pdf

mechanical final year design project

mechanical engineering final year project ppt

m.tech mechanical final year projects

agriculture based mechanical engineering final year projects

final year projects for mechanical engineering related to automobile

mechanical engineering final year project analysis

mechanical final year project buy

best mechanical final year projects

final year mechanical projects done by iit students

buy final year projects for mechanical engineering

b.tech final year projects for mechanical engineering